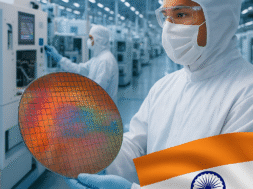

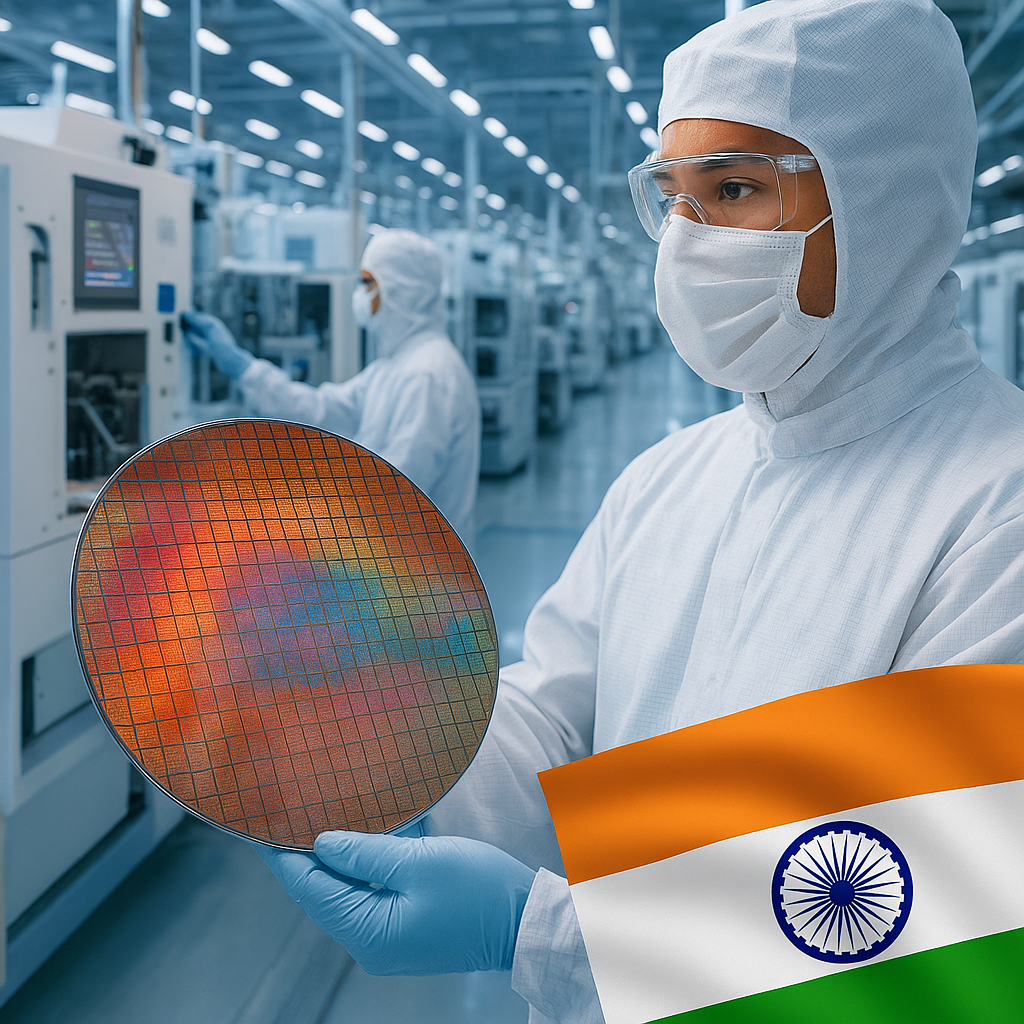

India’s $18 Billion Bet on Semiconductors: Can It Build the Next Global Chip Powerhouse?

NEW DELHI — India has set its sights on becoming a major player in the global semiconductor industry, pledging investments worth 1.6 trillion rupees ($18.2 billion) to build a full-fledged chip ecosystem.

The push comes as nations worldwide race toward semiconductor self-reliance, following U.S. restrictions on advanced chip exports to China in 2022. For India, this is both an opportunity to reduce dependency on imports and a chance to capture market share in the global electronics supply chain shifting away from Beijing.

Currently, India — one of the world’s largest electronics consumers — contributes little to chip manufacturing. To change this, New Delhi’s “Semiconductor Mission” aims to establish an end-to-end ecosystem, spanning design, fabrication, testing, and packaging.

The Ambitious Roadmap

So far, India has approved 10 semiconductor projects, including two fabrication plants and several assembly, testing, and packaging units. Leading the pack is Tata Electronics’ $11 billion fab in Gujarat, developed in partnership with Taiwan’s Powerchip Semiconductor Manufacturing Corp. This facility will produce chips for AI, automotive, data storage, and high-performance computing.

Another project involves the U.K.’s Clas-SiC Wafer Fab teaming up with India’s SiCSem to build the country’s first commercial compound semiconductor fab in Odisha, with applications in defense, EVs, consumer electronics, and renewable energy.

Despite these high-profile projects, experts warn that India needs more than “shiny objects.” A successful chip industry requires a deep ecosystem of suppliers, talent, logistics, and strong intellectual property laws.

Policy Support and Incentives

The Indian government has rolled out generous subsidies, covering up to 50% of project costs for fabs and testing facilities. It also introduced a new scheme to support electronic component manufacturing, ensuring that chipmakers have a domestic supply base.

Previously, New Delhi focused incentives only on fabs producing 28nm or smaller chips — crucial for AI and quantum computing. But policymakers have since broadened the support to encourage wider industry participation.

Challenges Ahead

Industry leaders point out that semiconductor fabs need ultra-clean chemical suppliers, stable logistics, flood- and vibration-free sites, and reliable power connectivity. These remain hurdles for India.

Additionally, while India has a strong semiconductor design workforce (thanks to global firms outsourcing block-level design validation since the 1990s), core intellectual property for cutting-edge chips still resides in the U.S., Taiwan, and Europe.

To go further, India may need to strengthen IP laws and enforcement, ensuring global players trust the country with high-value design and innovation.

The Global Race

The semiconductor battle is heating up, with TSMC (Taiwan Semiconductor Manufacturing Co.) preparing to mass-produce 2nm chips later this year. India is unlikely to catch up immediately but is positioning itself as a key player in assembly, testing, and mid-level fabrication — areas with high growth potential and lower entry barriers.

PwC India’s Sujay Shetty notes that the next 3–4 years will be critical for India. Success will depend on whether these projects can move beyond incentives into fully operational fabs and supporting infrastructure.

If successful, India could establish itself as a credible alternative to China in the global chip supply chain, boosting both its tech independence and geopolitical leverage.